Advanced HDPE Pipe Solutions for New Zealand

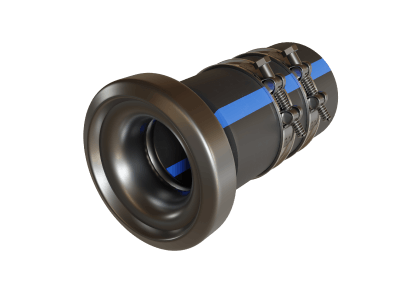

Cutting-Edge Bauer Couplings:

Every Anaconda HDPE pipe is equipped with highly versatile and cost-effective Bauer couplings. These innovative fittings simplify pipe connection and disconnection, reducing both labor and time while ensuring efficient adjustments on-site.

Customizable Thickness Options:

Anaconda offers HDPE pipes in three different thickness categories: DR11, DR17, and DR26. This variety allows customers to choose the optimal pipe thickness to meet the unique requirements of their projects, guaranteeing peak performance across diverse applications.

Flexible Ownership Options:

New Zealand Pump and Dredge ensure flexibility by offering both rental and purchase plans for Anaconda HDPE pipes. This adaptability empowers clients to manage budgets effectively, with rental options catering specifically to short-term projects. Contact us for detailed rental terms.

Tailored to Your Needs:

Anaconda Pipe and Hose provide comprehensive customization options, allowing clients to specify:

- Preferred diameters.

- Desired lengths.

- Material compositions.

This level of customization ensures that each HDPE pipe solution aligns perfectly with the demands of specific industrial operations.

Versatile Industrial Applications:

Designed for durability and flexibility, Anaconda HDPE pipes are ideal for transporting liquids, managing chemicals, and supporting diverse industrial fluid systems. Built to endure harsh conditions, they deliver reliable performance in even the most challenging environments.

Seamless Fitting Compatibility:

Anaconda HDPE pipes are engineered to work effortlessly with various fittings, including threaded connections, Bauer couplings, ANSI flanges, and other standard fittings. This compatibility ensures robust, leak-proof installations.

Ready to Simplify Your Piping System?

Streamline your operations with straight lengths of HDPE pipes that eliminate the need for fittings. Enjoy enhanced flow efficiency, reduced maintenance demands, and an effortless installation process. Our experienced team is here to help you find the perfect HDPE piping solution customized to your project’s needs.

Contact us today to learn how our innovative HDPE solutions can boost your operational efficiency and drive exceptional performance. Let’s build a smarter, more efficient piping system together!

Engineered for Industrial Excellence

Anaconda Pipe & Hose’s industrial HDPE pipes are designed to excel in the most demanding environments. Renowned for their seamless connection and disconnection capabilities, these pipes stand out for their versatility and efficiency. Featuring adaptable Bauer fittings, they offer unparalleled modularity, enabling quick adjustments to meet evolving project requirements.

Constructed from premium-grade materials, Anaconda HDPE pipes are built to withstand harsh conditions, providing exceptional resistance to extreme temperatures, high pressures, and corrosive environments. Their advanced protective coatings enhance corrosion resistance, ensuring a longer operational lifespan, even in the most challenging settings.

Precision Engineering for Superior Performance

With meticulous engineering, Anaconda HDPE pipes deliver precise dimensional accuracy, ensuring seamless integration with a variety of fittings and minimizing the risk of leaks. They strike the ideal balance between flexibility for adaptable installations and rigidity for maintaining structural strength under operational pressures.

Each pipe undergoes comprehensive quality assurance, including rigorous testing and strict adherence to industry standards. This commitment to quality makes Anaconda Pipe & Hose a trusted provider of dependable HDPE piping solutions tailored to meet the complex needs of diverse industrial applications.

Discover the reliability and durability of Anaconda HDPE pipes—engineered for precision and built to perform in any industrial setting.

Optimizing Industrial Pipe Systems with Bauer Fittings

Bauer fittings, widely recognized for their quick-connect functionality, have become indispensable in industrial pipe systems across sectors such as wastewater management, irrigation, construction, and mining. Known as Bauer Couplings, these fittings facilitate rapid and secure connections, reducing downtime and ensuring leak-proof operations that enhance system reliability and protect the environment.

Unmatched Versatility and Durability

A key advantage of Bauer fittings lies in their adaptability. They integrate seamlessly with various pipe materials and sizes, making them an ideal choice for diverse fluid transport requirements. Constructed from robust materials like high-grade galvanized or stainless steel, Bauer fittings are built to endure harsh industrial conditions, extending their lifespan and minimizing the need for frequent replacements.

The efficient sealing system in Bauer fittings guarantees leak-free connections, even when handling challenging substances like corrosive chemicals or slurries. Their flexibility in accommodating a wide range of pressures further enhances their suitability for numerous industrial applications.

Streamlined Design for Maximum Efficiency

Bauer fittings are engineered for simplicity and efficiency. Their quick-locking mechanism makes them incredibly user-friendly, allowing for easy installation and operation. This design reduces the need for specialized skills and eliminates complex processes like pipe fusing or welding, streamlining maintenance and repairs.

Additionally, Bauer fittings are compatible with a variety of pipe brands and materials, offering unparalleled flexibility. Companies can easily maintain and upgrade their systems without the hassle of sourcing specific components.

Cost-effective and Customizable Solutions

With their low maintenance requirements and cost-effective design, Bauer fittings are a reliable solution for optimizing fluid handling operations. A wide range of accessories is available, enabling customization to meet the unique demands of different industries.

Whether your operation involves transporting wastewater, managing corrosive fluids, or supporting high-pressure systems, Bauer fittings provide a durable, efficient, and versatile solution tailored to your industrial needs. Upgrade your pipe systems with Bauer fittings to experience improved performance, reduced downtime, and long-term cost savings.

The Advantages of Using Straight Lengths of HDPE Pipes Without Fittings

In many industrial applications, opting for straight lengths of HDPE pipes without fittings offers a range of operational and technical benefits, making them a preferred choice for fluid transport systems.

1. Enhanced Flow Efficiency

Straight lengths of HDPE pipes eliminate the need for multiple fittings, providing an uninterrupted flow path. This design minimizes friction and turbulence, improving flow dynamics and overall system efficiency. With fewer abrupt changes in direction, fluid systems can operate more smoothly, ensuring optimal performance across various industrial environments.

2. Simplified Installation and Maintenance

The absence of fittings reduces the complexity of installation, saving time and labor. Straight pipes are easier to handle, align, and connect, particularly in large-scale piping networks. Additionally, fewer components mean reduced risks of wear and failure, lowering maintenance demands and cutting long-term costs.

3. Improved Structural Integrity

The continuous nature of straight HDPE pipe lengths enhances the structural integrity of the pipeline. This is especially important in environments where resistance to external forces and stability are critical. Fewer connections also reduce the chances of leaks, which is vital for systems transporting hazardous or sensitive materials, ensuring environmental protection and operational safety.

4. Cost-Effectiveness

Straight lengths of HDPE pipes can result in significant cost savings. Without the need for fittings, projects can save on materials and labor expenses. This approach is particularly advantageous for applications that don’t require frequent connections or directional changes, making it an economical solution for long-term operations.

5. Tailored Suitability for Specific Applications

While straight lengths of HDPE pipes offer numerous benefits, it’s essential to evaluate their suitability for specific projects. Applications that demand frequent connections or adjustments may benefit more from fittings like Bauer or ANSI, which offer greater flexibility and convenience. Consulting with engineering professionals and adhering to industry standards ensures that the best configuration is chosen for the project’s requirements.

In conclusion, straight lengths of HDPE pipes without fittings provide smoother fluid flow, simplified installation, enhanced durability, and cost savings, making them a highly efficient and practical choice for a variety of industrial applications.

Related Equipment

Pipes and Hoses

Our collection of durable pipes and hoses is made to handle the harshest environments in New Zealand. Available in different sizes and designs, they can transport abrasive and corrosive fluids with ease. Whether for industrial or commercial use, our pipes and hoses offer reliable performance, ensuring smooth and efficient fluid transfer. Built to last, they are the perfect choice for demanding operations. With their strength and adaptability, they are ideal for both short-term tasks and long-term projects. Trust our pipes and hoses to keep your operations running smoothly, no matter the conditions.