Reliable Flooded Suction Pumps

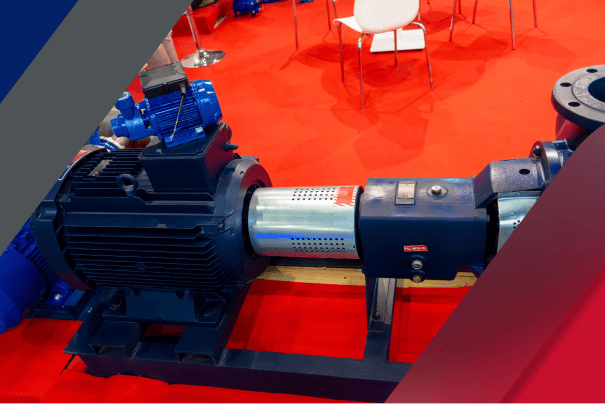

New Zealand Pump and Dredge offer strong and reliable flooded suction pumps. We provide both horizontal and vertical models made to handle tough pumping jobs. These pumps work well with thick, abrasive materials like sludge, slurry, and heavy solids. They are also built to perform even when fluid levels go up and down.

Our pumps are designed to last and perform in many industries around the world. Whether you need to move thick fluids or deal with challenging flow conditions, New Zealand Pump and Dredge have the right solution for your needs.

Affordable and Efficient Pumping Solutions

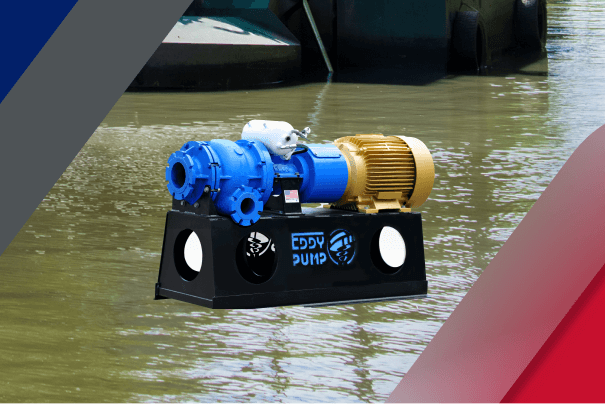

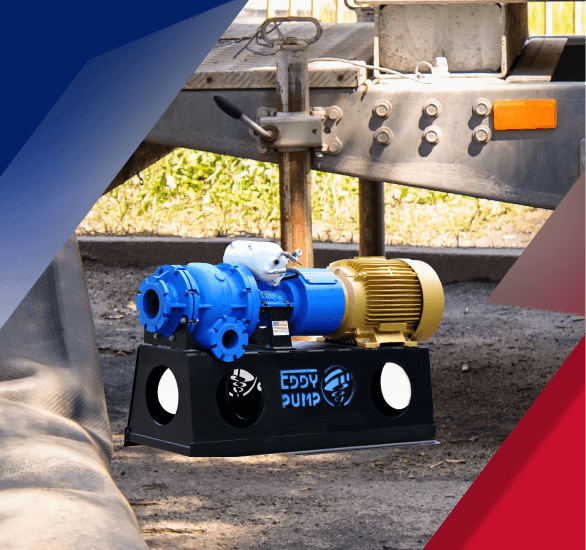

When it comes to tough jobs, the EDDY Pump is a reliable choice. Its smart design allows it to handle thick, abrasive materials smoothly without clogging. This makes it ideal for challenging applications.

With low maintenance needs, the EDDY Pump is not only easy to operate but also cost-effective, saving you time and money in the long run.

Unmatched Performance

The EDDY Pump is the perfect solution for high-flow and high-pressure tasks across various industries. It delivers reliable performance, even in the most challenging conditions.

Anti-Clogging Design

Designed to prevent clogs, the EDDY Pump handles large debris with ease. Its advanced design keeps operations running smoothly and safely, boosting overall efficiency.

Strength and Durability

Made from tough materials like high-chrome alloys, EDDY Pump systems are built to last. They provide long-term durability and dependable performance in the harshest environments.

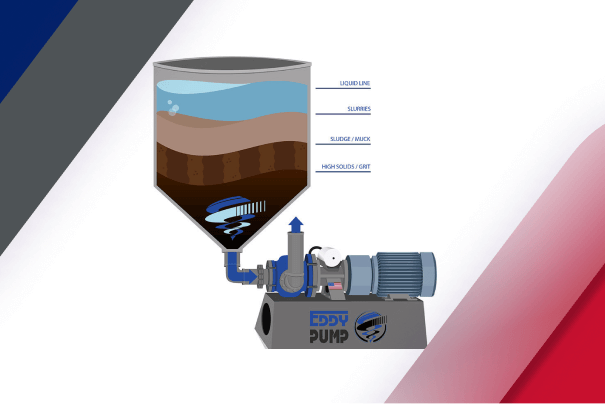

Gravity-Assisted Pumping for Tough Fluids

Flooded suction pumps are commonly used in industries like wastewater treatment, mining, and construction. They are great at handling thick fluids, sludge, and other tough materials.

These pumps work by placing the fluid above the pump’s inlet, letting gravity naturally push the fluid into the pump. This smart setup removes the need for pre-priming and keeps operations running smoothly and efficiently by combining natural forces with modern engineering.

Horizontal or Vertical Pumps: Which One Fits Your Needs?

When choosing between horizontal and vertical slurry pumps, it’s important to consider factors like fluid density, flow rate, pressure, distance, power source, temperature, pH levels, and resistance to corrosion or erosion.

Pumps made from high-quality materials not only perform better but also last longer. Our selection focuses on durable options that deliver reliable performance, even in the most demanding environments.

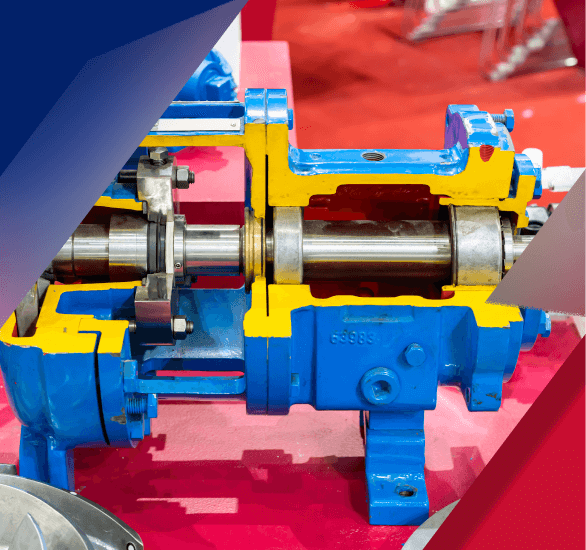

Horizontal Flooded Suction Pump

Easy Installation and Maintenance

Thanks to their simple design, horizontal flooded suction pumps are easy to install and require very little maintenance.

Higher Flow Rates

With a larger impeller, these pumps provide greater flow rates compared to other pump types, making them ideal for high-demand applications.

Lower NPSH Requirements

They perform well in situations where a lower Net Positive Suction Head (NPSH) is available, offering an advantage over vertical pumps.

Larger Space Requirements

However, their design means they need more floor space compared to vertical options.

Vertical Flooded Suction Pump

Compact and Space-Saving

With their compact design, vertical flooded suction pumps are ideal for tight spaces or hard-to-reach areas.

Highly Efficient

These pumps excel in applications that require significant surface lift, ensuring efficient performance.

Flexible Design

Their versatile structure allows them to be suspended or inserted directly into materials, making them adaptable for various pumping needs.

Maintenance Considerations

While highly effective, these pumps can be more challenging to repair and maintain compared to other designs.

The semi-automated dredge operates efficiently, requiring only 650 square feet of floor space and using less energy. It can handle deeper water levels without the need for onboard personnel.

Using three or four cables, the system includes electronically controlled winches for smooth navigation along a set dredging path, pump depth management, and RPM adjustments.

Globestar’s patented cable deployment system enables the dredge to operate at depths of up to 100 feet. With no internal structures, it can run 24 hours a day, ensuring continuous and reliable operation.

Key Considerations for Selecting a Flooded Suction Pump

Strong Pump Design

Choose a pump designed specifically for flooded suction tasks. It should be tough, reliable, and able to handle demanding jobs without breaking down.

Handles Solids and Tough Fluids

Flooded suction pumps are perfect for moving liquids with solids, like sludge, slurry, and other thick materials. They can handle debris, particles, and abrasive fluids without clogging or slowing down.

No Blockages

These pumps are built to let solids pass through smoothly, reducing the risk of blockages. This means fewer repairs, less downtime, and more time running efficiently.

High Efficiency

Flooded suction pumps work efficiently by keeping a steady, smooth flow of liquid. Their design helps avoid clogs, so you get better performance and save energy.

Long-Lasting Durability

Made with strong materials like stainless steel, cast iron, or tough plastics, these pumps resist wear and tear. This makes them last longer, even when pumping rough or abrasive fluids.

Cost-Effective Solution

These pumps are a great investment for handling tough fluids at a lower cost. Make sure the pump’s flow rate matches your needs for the best results and performance.

Handles Pressure Well

Check if the pump can lift the fluid to the required height (head pressure) without losing efficiency. A strong pump will perform well even under pressure.

Compatible Materials

Different liquids need different pump materials. For example, some fluids need stainless steel or high-strength plastic to prevent damage or corrosion.

Powerful and Efficient Motor

The pump motor must have enough power to handle the fluid and flow rate you need. Thick or heavy liquids may need a stronger motor to keep things moving smoothly.

Leak-Free Seals

Look for pumps with high-quality seals that prevent leaks. This ensures the pump runs safely and efficiently without wasting fluids.

Easy to Install and Maintain

Choose a pump that’s easy to set up and simple to maintain. Repairs should be straightforward, and spare parts should be easy to find when needed.

Safety Features

Safety is important. Good pumps have features like overload protection, temperature sensors, and safety guards. These protect the pump and prevent damage during operation.

Reliable Manufacturer

Buy from a trusted company with a reputation for making high-quality, dependable pumps. A good manufacturer will also offer strong customer support when you need help.

Key Advantages of Advanced Pump Technology

Handles Fluids with Solids

These pumps are designed to move liquids with a high amount of solids, like slurries. They can easily manage fluids with particles, debris, or rough, abrasive materials without losing performance.

Reduces Clogging

The smart design of these pumps allows solids to pass through without blocking the system. This reduces downtime and lowers the need for frequent repairs or maintenance.

Improved Efficiency

Submerged suction pumps are built to work smoothly, even with tough materials. They are less likely to get blocked, which helps increase flow rates and boosts overall efficiency.

Strong and Long-Lasting

Made from durable materials, these pumps are built to handle tough jobs. Their strong construction means they last longer and resist wear and tear, even in harsh environments.

Affordable and Reliable

Flooded suction pumps are a cost-effective solution for moving slurries and challenging fluids. They combine efficiency and reliability while keeping operating costs low, making them a smart choice for tough fluid-handling tasks.

Our pump models

Model | Diameter | Power | GPM Flow | Head |

DSP/HD 3000 | 3 inches | 43 HP | 100 – 780 | up to 130 feet |

DSP/HD 4000 | 4 inches | 43 HP | 250 – 1200 | up to 200 feet |

DSP/HD 4000 | 4 inches | 115 HP | 250 – 1200 | up to 200 feet |

DSP/HD 6000 | 6 inches | 115 HP | 450-2000 | up to 200 feet |

DSP/HD 6000 | 6 inches | 173 HP | 450-2000 | up to 200 feet |

DSP 8000 | 8 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 10000 | 10 inches | 550 HP | 1600 – 5000 | up to 240 feet |

DSP 12000 | 12 inches | 700 HP | 2600 – 7300 | up to 180 feet |

Benefits of Handling Slurries and Complex Liquids

Self-Priming Capability

Self-priming pumps can draw fluids on their own without extra equipment or steps. This makes setup easier and eliminates the need for additional priming processes.

Built to Last

These pumps are designed for durability. Advanced seals like o-rings, mechanical seals, and liners protect the pump from damage caused by harsh, abrasive fluids. This ensures longer-lasting performance and reliability.

Versatile for Many Applications

Submersible suction pumps are highly adaptable. They can handle various fluids, including sludge and liquids with high solid content. These pumps are widely used in mining, construction, industrial operations, and water treatment.

Low Maintenance

Thanks to their sturdy design and efficient operation, these pumps need less maintenance. This reduces downtime, lowers repair costs, and keeps operations running smoothly.

Reliable and Smooth Operation

Flooded suction pumps ensure a constant flow of fluid, which helps prevent vibration and keeps the pump running smoothly and consistently.

Related Equipment

Slurry Pumps

Our slurry pumps are made to handle tough materials like thick mud, sand, and abrasive substances. Designed for strength and precision, these pumps perform exceptionally well in harsh conditions. They feature the latest innovations for durability and efficiency, making them ideal for industrial and mining operations across New Zealand. With their robust design, these pumps reduce downtime and maintenance needs, saving you time and money. Whether for challenging terrain or heavy-duty use, our slurry pumps are built to last.